PRODUCTS

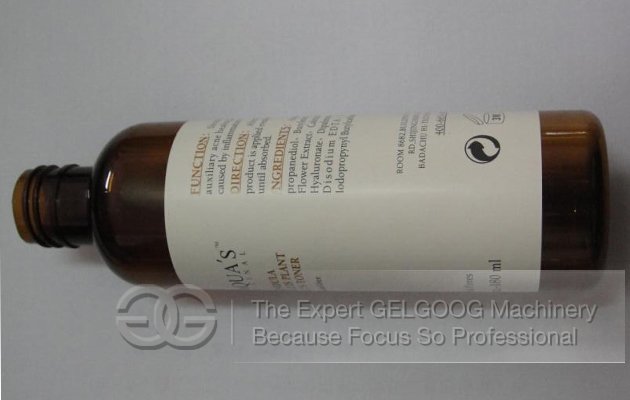

Manual Labelling Machine For Bottle

- MOQ:1 /Sets

- Brand:GELGOOG MACHINERY

- Certification: CE

- Supply Ability: 10 Set/Sets Per Month

- PAY METHOD: WEST UNION L/C T/T CASH

- Warranty Time: 12 Months

- LOADING PORT: Qingdao Port|Tianjin Port

- Country Of Origin: China

Application

Designed for beer, beverage, pure water, fruit juice, milk products, etc.,packaging production line

Main Feature

Good effect heat packing, easy operation, fine quality, ideal equipment for heat shrink packing.

Features

Manual Labelling Machine For Vertical Bottle is mainly used in cosmetics, food, cosmetic, pharmaceutical and other industries of product labeling. Suitable for labeling round bottle containers, double label round bottle, a single tag round bottles, with code label round bottle labeling, such as: glass bottle, plastic bottles, tins and the first class.

Introduction of Manual Labelling Machine:

1. This labeller adopts automatic human-machine interface, with simple operation. Simply click can complete the corresponding action;

2. The main components are all made of stainless steel, meeting the national standards;

3. Tags automatically count, can record every shift production, convenient for production management;

4. The machine automatically stop when the labelling is finished. It can be set per shift production quantity, stop automatically after use.

Working Principle of Manual Labelling Machine:

The Labeling Machine works according to the light check. When the machine checked the product , the system will send the message to the control system , then the control system will compand the Photoelectric Sensors , the label avilable, the machine will feedback the system , and will run the machine , date printing and finish the labeling .

Performance Characteristics of Manual Labelling Machine:

1. Imported electromagnetic clutch and high precision.

2. Advanced anodizing aluminum alloy, longer life.

3. Using the best motor can meet the heavy load, and long time operation.

4. All parts and standard adopt stainless steel material.

5. PLC control, human-machine interface control panel is more fashionable.

6. Adopt Import inspection standard optical coupling, to guarantee the high precision accuracy.

7. Label Single or double tags round bottle.

Technical Data

| Model | GG-4535 |

| The furnace chamber size | 1200*450*350mm |

| speed | 0-15m/min |

| Max load weight | 25kg |

| Voltage and power | 380V 16kw 3phases |

| Machine size | 2200/730*1440mm |

| weight | 200kg |

| Packing material |

PE film |

FAQ

1. How can i ensure the machine i received is undamaged?

→ Before delivering the goods, we will send you the pictures of the product and the package. Before signing in, make sure the pakage is undamaged. If any question happens, pls contact me as soon as possible.

2. I want ro make an order, which kind of payment mode will your conpany accept?

→T/T, Western Union, L/C, and Money Gram.

3. What should I do if i meet trouble while using?

→Don't worry about it. If there is any question, pls contact us as soon as possible. Our professional engineers will solve the problem for you. Just let us know your problem.

4. If i order this machine from you, when will you deliver this machine for me?

→After you make the payment, we usually deliver the machine within 7 working days.

0086-371-63398802

0086-185-3993-1566

No.100 Shangdu Road, Zhengdong New District, Zhengzhou City, Henan Province, China

CONTACT US

Copyright © 2010 - Henan GELGOOG Machinery Co.,LTD

Links:Packing Machine | Wafer Biscuit Machine |