PRODUCTS

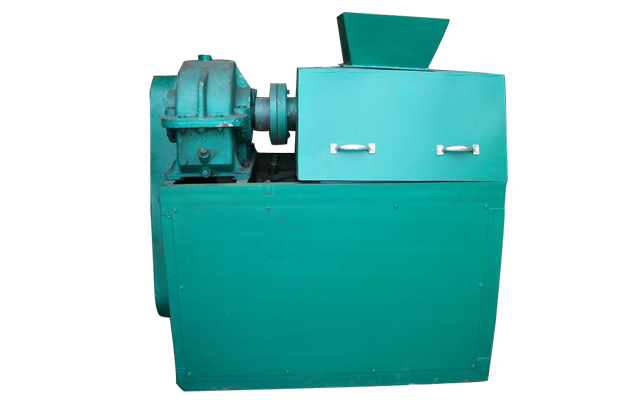

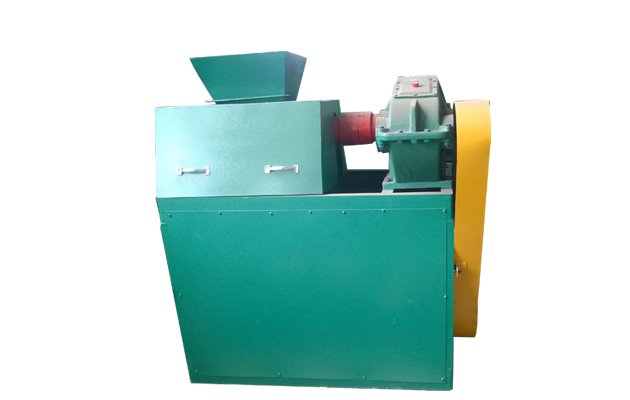

Manure fertilizer pellet machine GGJ-1

- MOQ:1 /Sets

- Brand:GELGOOG MACHINERY

- Certification: CE

- Supply Ability: 10 Set/Sets Per Month

- PAY METHOD: WEST UNION L/C T/T CASH

- Warranty Time: 12 Months

- LOADING PORT: Qingdao Port|Tianjin Port

- Country Of Origin: China

Application

For the manure fertilizer pellet machine kinds of dry powders enter the machine

and squeezed and shaped by the double roller forces. After crushing and screen

ing, the granule is pelletized.

Main Feature

Saving energy and reducing consumption, without waste discharge, stable operation,

reliable operation, convenient maintenance.

Features

1、Manure fertilizer pellet machine, which is no dry normal production process,

a shape,capacity can be 1-1.5t/h,1.5-3t/h,with advantage of low investment and quick,

good economic returns.

2、Dry material powder is fed from the top of the pellet machine, desaeration, screw-

pre-press,enter into the gap between the two rollers that are rotating in opposite directions.

3、The smashed material enters into granulator, and then the particles and part of powder

material enters into sieve by the rolling knife, and then the product is separated.

4、The pressed material falls down because of surface tension and gravity when passes through

pressing section.

5、The noddies shaped material then enters into breaking machine, been smashed by rotating

knife.

6、The product up to standard will be conveyed to product silo by conveyor; the material under

the sieve should be fed back and should be pressed again.

7、The pressure might adjust by the hydraulic oil cylinder according the requirements of granu

lation. Sheet,bar and other shape of product might be procured by choose the relative shape of

the grooves on the surface of the roller.

Technical Data

| Model | GGJ-1 |

| Power | 11KW |

| Capacity | 1t/h |

FAQ

Question: What is the scope of application?

Answer:

For the manure fertilizer pellet machine kinds of dry powders enter the machine

and squeezed and shaped by the double roller forces. After crushing and screen

ing, the granule is pelletized.

Question: What are the main characteristics of the machine?

Answer:

Saving energy and reducing consumption, without waste discharge, stable operation,

reliable operation, convenient maintenance.

Question: Please give a brief introduction to the advantages of the machine.

Answer:

The manure fertilizer pellet machine can produce all kinds of concentration and types

fertilizer(including organic fertilizer, inorganic fertilizer, biological fertilizer, magnetic

fertilizers, etc.) compound fertilizer,especially the rare earths, potash, producyion series

compound fertilizer granulation.

fertilizer(including organic fertilizer, inorganic fertilizer, biological fertilizer, magnetic

fertilizers, etc.) compound fertilizer,especially the rare earths, potash, producyion series

compound fertilizer granulation.

Manure fertilizer pellet machine uses squeezing principle to form fertilizer particles with

diameters of 3.5-10mm in one time.It has higher granulating ratio of over 85%. Double

roller fertilizer granulator is the most popular granulating methods in no-drying (2%-5%

moisture content) fertilizer process at room temperature.Less cost and quick granulating,

thus it can bring fertilizer investment a good economic returns.

diameters of 3.5-10mm in one time.It has higher granulating ratio of over 85%. Double

roller fertilizer granulator is the most popular granulating methods in no-drying (2%-5%

moisture content) fertilizer process at room temperature.Less cost and quick granulating,

thus it can bring fertilizer investment a good economic returns.

0086-371-63398802

0086-185-3993-1566

No.100 Shangdu Road, Zhengdong New District, Zhengzhou City, Henan Province, China

CONTACT US

Copyright © 2010 - Henan GELGOOG Machinery Co.,LTD

Links:Packing Machine | Wafer Biscuit Machine |