Market Potential for Biomass Pellets

Market Potential for Biomass Pellets

Biomass particles is a general term used to describe the heat generated by renewable resources and energy of the fuel pellets. Where wood pellets are the most common type. Wood pellets are compressed sawdust size of the wood fiber. Particle diameter of the cylindrical timber is of a standard size and the length of 6 to 8mm diameter is four times. In the past few years to promote the growth of wood pellets market, which is why?

Reasons for the growth of the pellet fuel market

The first reason can be the consistent accelerating of the fossil fuels price and price instability.

The second comes form the environmental aspects, people give increased attention on the damage of fossil fuels to the environment.

Third reason is that wood pellets can be produced locally and made form various biomass materials.

Then the reasons can be the advantages of wood pellets, such as their compact size and portability, high energy density and low moisture content, which make wood pellets become a renewable energy sources.

The second comes form the environmental aspects, people give increased attention on the damage of fossil fuels to the environment.

Third reason is that wood pellets can be produced locally and made form various biomass materials.

Then the reasons can be the advantages of wood pellets, such as their compact size and portability, high energy density and low moisture content, which make wood pellets become a renewable energy sources.

Why wood pellets instead of logs?

People may confused about why people using wood pellets to generate heat and energy, why not just burn logs?

First, logs come form trees that grow slowly in general, while wood pellets can made form various materials which include straws, grasses, energy crops, etc.

Second, wood pellets can be burnt much more efficiently which means pellets can produce less ash, less smoke and more heat.

First, logs come form trees that grow slowly in general, while wood pellets can made form various materials which include straws, grasses, energy crops, etc.

Second, wood pellets can be burnt much more efficiently which means pellets can produce less ash, less smoke and more heat.

Materials for biomass pellets

Hemp is one of the most promising materials for wood pellets production. Hemp can be grown on land unsuitable for most food crops. Besides, it only takes 3 months for hemp from seed to harvest. Further more hemp pellets have very similar combustion energy to most wood pellets and produce similar ash content to standard grade wood pellets.

Saw milling residues. Planer shavings and sawdust are another feed stocks for wood pellets production. Saw milling residues are the byproduct of lumber manufacturing process, so using these materials to make wood pellets could largely reduce the cost. Besides, using saw milling residues to make wood pellets requires little or no drying, which could also reduce making procedure.

Straw or crop residue harvesting. After harvesting, all kinds of straw can be used to make wood pellets. These materials are generally considered to be useless, perhaps burned in the explosion scene. Production of these materials into valuable wood pellets can make crop production more profitable.

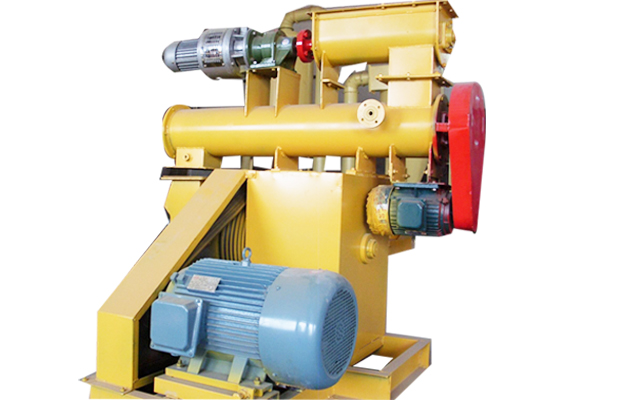

Biomass pellet market continues to expand, and there is great demand. Wood pellet machine that can help you better start this business.

0086-371-63398802

0086-185-3993-1566

No.100 Shangdu Road, Zhengdong New District, Zhengzhou City, Henan Province, China

CONTACT US

Copyright © 2010 - Henan GELGOOG Machinery Co.,LTD

Links:Packing Machine | Wafer Biscuit Machine |