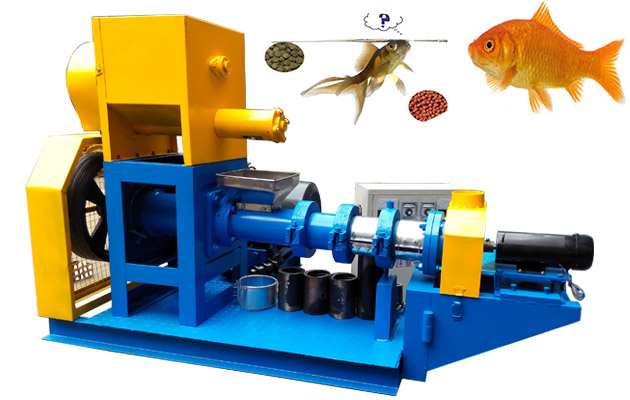

Fish Feed Extruder Machine For Making Floating Pellets

This series small fish feed extruder use the motor as the driving force for initiative axis, and operate cyclely. Major axis and disk mode are drived by gear wheels to produce the friction with the pressure roll bolt, the resulting friction temperature ( between pressure roller and the mode tray can reach 80°c . The powder material become paste at high temperature and is condensed into pieces, then go through the hole on the mode tray.

Advantages of Fish Feed Extruder:

1.the pelleting process in the feed mill machine under its own pressure, the starch can feed a certain degree of ripening, to produce a concentrated flavor, hard texture and feed, in accordance with pigs, cattle, sheep, rodents eating biological characteristics, improve feed palatability,

2. particle formation process enables cereals, legumes trypsin resistance factor denaturation role in reducing the adverse effects on digestion, the high temperature can kill a variety of parasite eggs and other pathogenic microorganisms, reducing the variety of parasitic diseases and gastrointestinal system disease.

3. the pellet mill is feeding convenient, high efficiency, easy to control the amount fed to save feed, clean and sanitary. Especially for fish, because pellets slowly dissolve in water, sediment will not be flooded, can reduce waste.

4. templates and pressure roller with high wear materials refined, has a long life, reasonable structure, strong and durable.

0086-371-63398802

0086-185-3993-1566

No.100 Shangdu Road, Zhengdong New District, Zhengzhou City, Henan Province, China

CONTACT US

Copyright © 2010 - Henan GELGOOG Machinery Co.,LTD

Links:Packing Machine | Wafer Biscuit Machine |